Engineering Services

With over 25 years of experience in the field of accident reconstruction and thousands of inspections performed, Asay Engineering can provide a detailed accurate analysis that is tailored specifically to each unique collision event. Whether the evidence has been preserved or not, there are scientific techniques available that allow for a detailed analysis to be performed. Feel free to contact us directly for a more case-specific assessment.

Site and Vehicle Inspections

Wherever accidents occur, it is important to accurately and appropriately identify, document, and quantify the evidence and geometry of the accident site and the vehicles involved for later analysis. Each inspection is unique and tailored to the evidence that is to be collected and preserved; therefore, Asay Engineering utilizes various state-of-the-art systems and processes in order to capture and preserve the case-specific information.

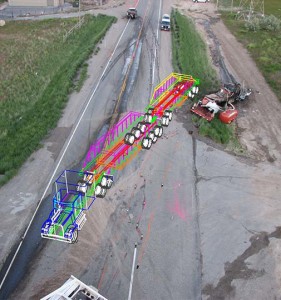

Collision Analysis and Simulation

Collisions range in complexity and therefore the ability to analyze them depends primarily upon the model and the parameters used to simulate the physics of the event. The ability to apply known values from tests and make the appropriate assumptions in order to model the event is crucial in the simulation process. Therefore, Asay Engineering, depending upon the type of collision, utilizes various proven scientific models.

Performance and Design Testing

Many times, published values for performance parameters are sufficient, but when it is necessary to measure either the performance of a vehicle or the behavior of a particular component, Asay Engineering has the ability to accurately and adequately do so.

Failure Analysis

Sometimes, what appears to be normal operating machinery, will suddenly fail without any apparent warning or explanation. Upon further analysis, subtle warning signs may have been present, but were either overlooked or undetected. Asay Engineering has the ability to document and explore those failure modes and mechanisms.

Testing and Research

Conventional crash tests are conducted at state-of-the-art facilities with a budget that is many times cost prohibitive for other smaller entities. Since 1999, an alternative to conventional crash testing has proven to be both efficient and cost effective. The ability to use the Massive Moving Barrier (MMB) as a crash test device has provided the means to conduct impact and rollover testing that previously were cost prohibitive. Asay Engineering continues to utilize this test device in conducting an on-going research program.